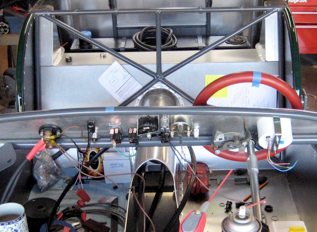

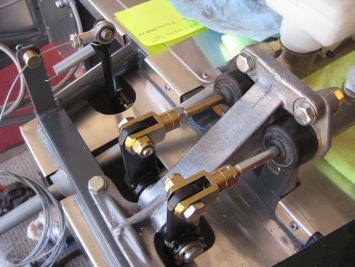

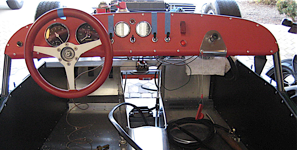

My S2 7 project is now underway ..... I thought it might be interesting for some enthusiasts out there to see a step by step build up. Not a completely standard restoration but I think tastefully modified.

I had been waiting quite a while for the chassis to come from England. Most of the delay was having it painted. I dread to think how many hours I spent polishing the body on my race 7. As you can see in the picture on the home page, I kept all the alloy polished.

This time all I have to is a wax job. Get that crate open and full steam ahead .....

The plan is to build the car as a fast street machine, also to be a good track day car and perhaps even the occasional vintage race.

I hope you enjoy the 7 as it grows, pictures will be added regularly.